The build v1

I have just been designing the prop Hub/Bearing assembly On A9cad this is a free Cad software but very similar to Autocad.

I'm not the best on this but it gives me an idea of sizes and the scale parts need to be.

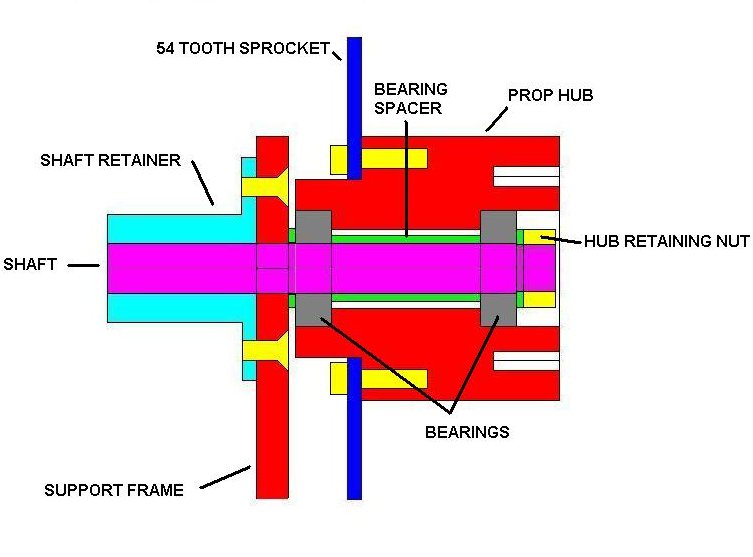

Prop Hub - This will be machined from aluminium bar

Sprocket - This will be modified to fit over the prop hub and secure in place with M6 Cap screws

Bearings - 1 Angular contact bearing closest to the shaft retainer to take axial forces

1Standard ball race on the front to take radial forces, both 35mm x 15mm x 11mm

Shaft - 15mm ground silver steel bar, turned down and m14 fine thread added to hub nut end

Spacer - steel tube spacer between inner ball races so hub can be tightened with out applying load to bearings

Support frame - 10mm aluminium

Shaft retainer - Made from steel to support shaft then bolted into position on frame with M6 counter sunk screws

Ive had some time to build now and made some progress with the motor and support frame.

The motor was stripped down and the bearings checked for quality, i also had to put some high temperature epoxy on the motor windings as they where slightly loose and i didnt want them touching any moving parts.

The frame was made as shown so the distance between the motor and propeller hub could be adjusted to increase or decrease the chain tension.

The above picture shows the sprocket mounted to the motor and the propeller hub machined with the bearing and propeller .